- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

Buttons & Button Supplies

PROBLEM SOLVING TIPS 1. Material does not fold uniformly into a button.

Align button covering dies front to back.

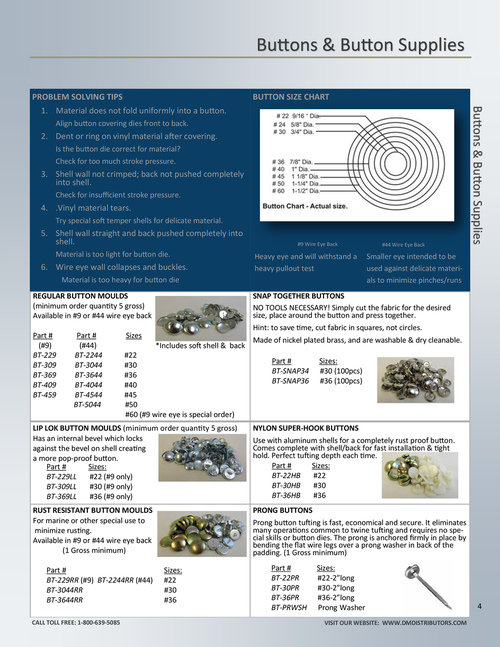

BUTTON SIZE CHART

Buttons & Button Supplies

2. Dent or ring on vinyl material after covering.

Is the button die correct for material? Check for too much stroke pressure.

3. Shell wall not crimped; back not pushed completely into shell.

Check for insufficient stroke pressure.

4. .Vinyl material tears.

Try special soft temper shells for delicate material.

5. Shell wall straight and back pushed completely into shell.

Material is too light for button die.

#9 Wire Eye Back

#44 Wire Eye Back

6. Wire eye wall collapses and buckles.

Material is too heavy for button die REGULAR BUTTON MOULDS (minimum order quantity 5 gross) Available in #9 or #44 wire eye back Part # (#9) BT-229 BT-309 BT-369 BT-409 BT-459 Part # (#44) BT-2244 BT-3044 BT-3644 BT-4044 BT-4544 BT-5044 Sizes *Includes soft shell & back #22 #30 #36 #40 #45 #50 #60 (#9 wire eye is special order)

Heavy eye and will withstand a heavy pullout test

Smaller eye intended to be used against delicate materials to minimize pinches/runs.

SNAP TOGETHER BUTTONS NO TOOLS NECESSARY! Simply cut the fabric for the desired size, place around the button and press together. Hint: to save time, cut fabric in squares, not circles. Made of nickel plated brass, and are washable & dry cleanable. Part # BT-SNAP34 BT-SNAP36 Sizes: #30 (100pcs) #36 (100pcs)

LIP LOK BUTTON MOULDS (minimum order quantity 5 gross) Has an internal bevel which locks against the bevel on shell creating a more pop-proof button. Part # Sizes: BT-229LL #22 (#9 only) BT-309LL #30 (#9 only) BT-369LL #36 (#9 only) RUST RESISTANT BUTTON MOULDS For marine or other special use to minimize rusting. Available in #9 or #44 wire eye back (1 Gross minimum) Part # BT-229RR (#9) BT-2244RR (#44) BT-3044RR BT-3644RR

CALL TOLL FREE: 1-800-639-5085

NYLON SUPER-HOOK BUTTONS Use with aluminum shells for a completely rust proof button. Comes complete with shell/back for fast installation & tight hold. Perfect tufting depth each time. Part # Sizes: BT-22HB #22 BT-30HB #30 BT-36HB #36 PRONG BUTTONS Prong button tufting is fast, economical and secure. It eliminates many operations common to twine tufting and requires no special skills or button dies. The prong is anchored firmly in place by bending the flat wire legs over a prong washer in back of the padding. (1 Gross minimum)

Sizes: #22 #30 #36

Part # BT-22PR BT-30PR BT-36PR BT-PRWSH

Sizes: #22-2”long #30-2”long #36-2”long Prong Washer

VISIT OUR WEBSITE: WWW.DMDISTRIBUTORS.COM

4